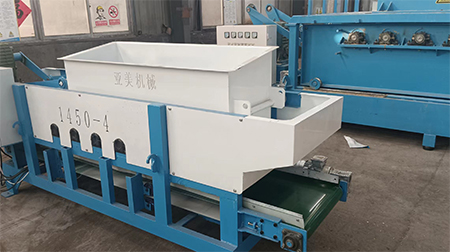

An industrial wood shaving machine is a piece of equipment designed to process wood into shavings

or flakes on a large scale. These machines are commonly used in industries such as woodworking, forestry,

and animal bedding production. The primary purpose of an industrial wood shaving machine is to efficiently

and uniformly produce wood shavings for various applications.

Key features and functions of industrial wood shaving machines may include:

1. Feed Mechanism: These machines often have a feeding mechanism that transports the wood material

into the cutting or shaving components.

2. Cutting Mechanism: The cutting mechanism typically consists of sharp blades or knives that cut the

wood into thin shavings or flakes. The design may vary based on the specific machine model.

3. Adjustable Settings: Many industrial wood shaving machines allow operators to adjust settings such

as thickness and length to produce shavings with specific characteristics.

4. Powerful Motor: These machines are equipped with powerful motors to handle the high-volume processing

of wood materials.

5. Collection System: There is usually a system for collecting and conveying the produced wood shavings

for further processing or packaging.

6. Safety Features: Industrial machines prioritize safety, often incorporating features such as emergency stops,

protective guards, and safety sensors.

The resulting wood shavings from these machines can be used for various purposes, including animal bedding,

biomass fuel, packaging material, or other applications in industries that require processed wood products.

Specific models and features may vary among manufacturers, so it's essential to choose a machine that suits

the intended application and production requirements. If you have more specific questions or need information

about a particular industrial wood shaving machine model, please provide additional details for a more targeted response.

English

English ch

ch اللغة العربية

اللغة العربية